failsafeseries

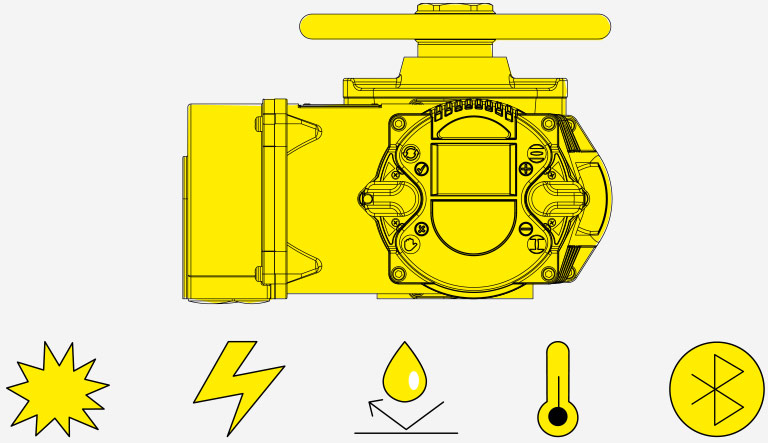

safe & reliable

A successful innovation

The SCHIEBEL failsafe technology is based on the idea of combining an electrical actuator with a purely mechanical safety function that operates independently of the power supply. If the power fails, fittings can be put in a predefined position in less than one second. It takes just a few steps to design the ideal failsafe actuator.

1 Basic choice

Explosion Protection

Power Supply

Corrosion Protection

Ambient Conditions

Network Connection

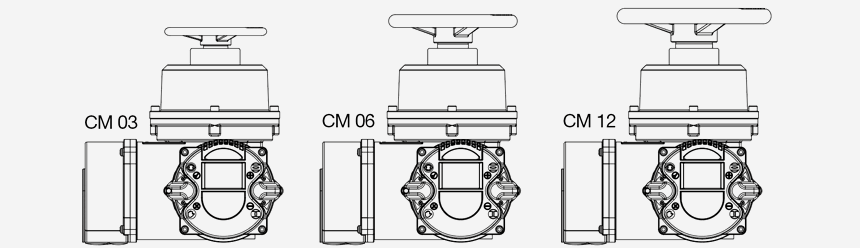

2 Size

In combination with the cm series, the innovative failsafe function is available for models of all sizes.

CM 03 up to 32 Nm

CM 06 up to 64 Nm

CM 12 up to 125 Nm

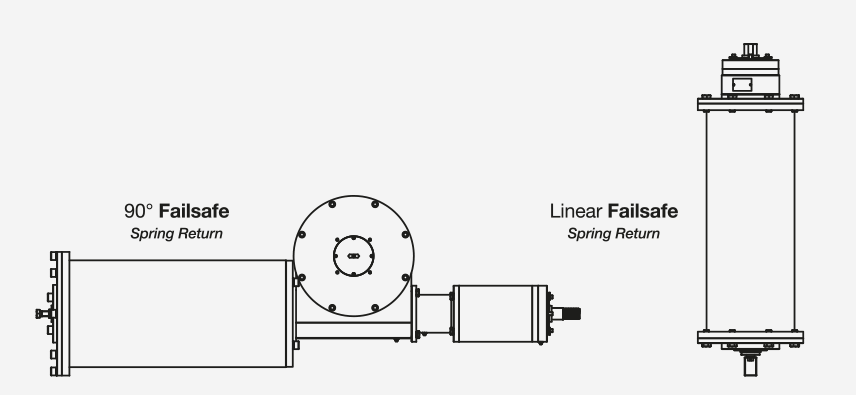

3 Components

Models of all sizes can be custom-expanded by adding various components.

failsafe series safety function

Technology

Safety Integrity Level (SIL) classification in accordance with IEC 61508 and reliability are at the core of SCHIEBEL‘s networked CM actuators, which are fitted with an optional failsafe function. Thanks to their sophisticated technology, they also offer excellent precision and speed control. High efficiency is the hallmark of the CM series. Low-wear and low-friction thread and gear components ensure a long service life. As a further option, an engageable handwheel assembly is available, which enables manual movement of the actuator (including spring) even when electrically de-energised.

Design

The intelligent functional design and high-grade materials raise the CM failsafe actuators to a new level of quality. During the design process, SCHIEBEL paid particular attention to ensuring that the centre of gravity is located directly above the valve; this has a beneficial effect in terms of weight distribution and assembly so that there are no problems with vibrations on the piping. Furthermore, the design of the units is very straightforward so they are easy for the end user to understand and operate.

Engineering

With its customer-specific solutions, SCHIEBEL offers all the software and hardware features that customers need for the use of failsafe actuators in their company. Thanks to in-house software engineering – one of SCHIEBEL‘s core competences – users can rely on optimal hardware coordination and advanced service support at all times.

Availability

CM actuators with failsafe function combine the advantages of electric drive and mechanical spring. Because of the lack of other technologies (e.g. hydraulic/pneumatic), as well as the simple design and sophisticated software options, accidental errors are reduced to a minimum, resulting in substantial cost savings in terms of operation, storage and servicing. In addition, an optional handwheel can be integrated in the unit.

Maintenance

The low-wear mechanical system with its frugal, highly energy-efficient electric drive with state-of-the-art power electronic modules and integrated energy-saving electronics reduces maintenance costs for the user. In addition, SCHIEBEL has integrated extensive monitoring and diagnostic functions into its actuators. Remote control features and SCHIEBEL‘s on-site service guarantee reliable operation.

Digitalisation

The sophisticated Smartcon control system developed in-house by SCHIEBEL ensures straightforward commissioning and simple, reliable operation. The control unit meets all requirements relating to digitalisation and IoT, as well as providing interfaces to all major fieldbus systems. In addition, the Single Pair Ethernet feature offers options for an auxiliary power supply (Power over Data Line).

Modular concept

CM actuators with failsafe function are based on SCHIEBEL‘s proven modular concept. The basic modular structure of the actuator can be combined with a number of different failsafe units. To make the selection of the actuator as straightforward and user-friendly as possible, SCHIEBEL has designed its 3-level concept. It has also ensured compatibility with a range of different supply and communication networks. Thanks to this tool, it is now easier than ever to find the right product for the particular application.

Solution

The failsafe function ensures that the actuator is quickly brought into a safe position in the event of an emergency. This is performed by means of a mechanically decoupled spring and therefore works even if the electrical power supply fails. It is possible to cover customer-specific requirements and problems thanks to the numerous options in terms of operation and parameterisation. Development activities at SCHIEBEL are always customer-oriented. No matter whether the requirement is for extremely fast positioning times or slow movement, CM actuators with failsafe function are able to meet these challenges.