smartcon

one interface makes it all

Smartcon for smart control

Smartcon is a modern, reliable and versatile control system that provides valuable information about the integrated actuator technology. Initially developed to combine aspects such as user friendliness, flexibility and reliability in a single control system, it has been optimized over the years with numerous additional features but its fundamental virtues remain totally intact.

Haptics

To ensure easy, error-free working with the control system, SCHIEBEL has paid great attention to the haptics of the unit. For example, it is possible to operate the system in the field using switches in any environment even with PPE. Users are able to rely on visual feedback about the switch position just as much as on the LED displays in the case of parameter changes. If an error occurs, a red backlight is immediately visible on the LC display.

Technology

Thanks to the Smartcon control system, SCHIEBEL electric actuators are highly intelligent units – and not just in terms of faults and troubleshooting. With Smartcon‘s integrated infrared and Bluetooth technology, as well as its menu-guided, project-oriented software tools, parameterisation in the field during commissioning is extremely simple and reliable. And the same applies when it comes to energy-efficient operation, which is ensured by the BLDC motor control on CM drives with low power loss as a result of perfectly integrated hardware and software interaction.

Digitalisation

In line with the trend towards comprehensive networking, the open protocol structures in the software and control system can be integrated into existing customer systems. The impact of Industry 4.0 is evident and interfaces are available to a large number of serial and TCP-based fieldbus systems, including Profibus, Modbus RTU, Modbus TCP, Ethernet/IP, DeviceNET, Ethernet Powerlink and HART protocol, which can be selected according to customer requirements. The system meets all the challenges of IoT. A special feature at SCHIEBEL is that the SMARTCON control system is used on all actuators – this ensures that the local user always works with the same control system, regardless of the application.

Flexibility

The Smartcon control system is impressively flexible, not just in terms of its menu navigation and the various languages – it can also be upgraded in the field. Since upgrading does not require any change in the hardware, software options can simply be uploaded by means of a code. Ongoing firmware upgrades make the control system future-proof. In addition, all settings can be selected non-intrusively.

Engineering

A core competence at SCHIEBEL is its own development of smart tool software. As the hardware and firmware engineering is also carried out in-house, perfect coordination in all aspects is guaranteed for special customer requirements. To be able to meet the requirements of different sectors, SCHIEBEL is constantly expanding its portfolio of specific software functions.

User friendliness

SCHIEBEL has integrated two variable, customer-selectable operating philosophies into its control system, which differ in terms of menu navigation and are based on the personal preferences of the user. In both variants, the menu navigation of the control system is intuitive and ensures that the individual functions are clearly recognisable at all times. In addition, Smartcon communicates in a wide range of customer languages, including German, English, Italian, French, Russian, Chinese and many others. In the case of special applications, the control system can also be designed as an operating unit separate from the actuator.

Security

Security is of particular importance in the world of IoT. To protect the control system from unauthorised access, SCHIEBEL uses Bluetooth communication and password protection. A sophisticated multi-level system of different user levels ensures that visibility and parameterisation are available only to authorised users. In addition, SCHIEBEL has provided for the installation mechanical locking options.

Operating data acquisition

The integrated and wide-ranging acquisition of operating and service-relevant data effectively supports customers in the planning and implementation of preventive maintenance measures and thus also contributes to long-term secure and stable operation. Here, too, integration into customer systems is possible thanks to the open protocol structures.

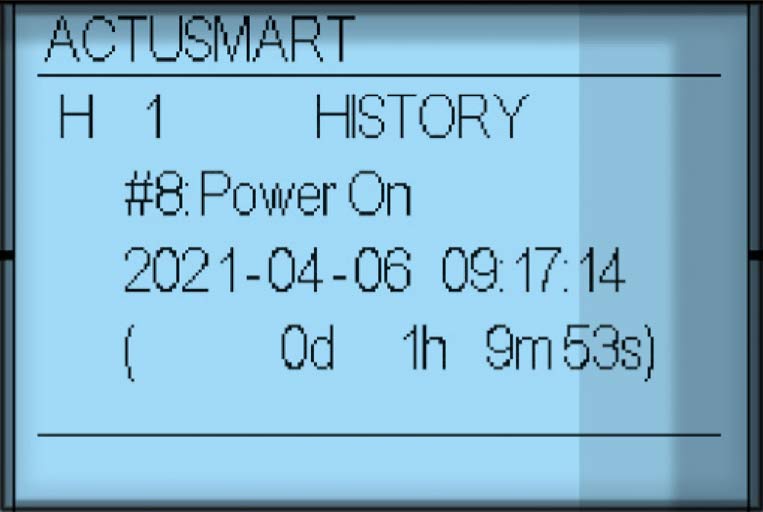

History

In the History status menu, events are continuously time-stamp logged and stored. Using SCHIEBEL software, up to 100 events can be tracked and displayed.

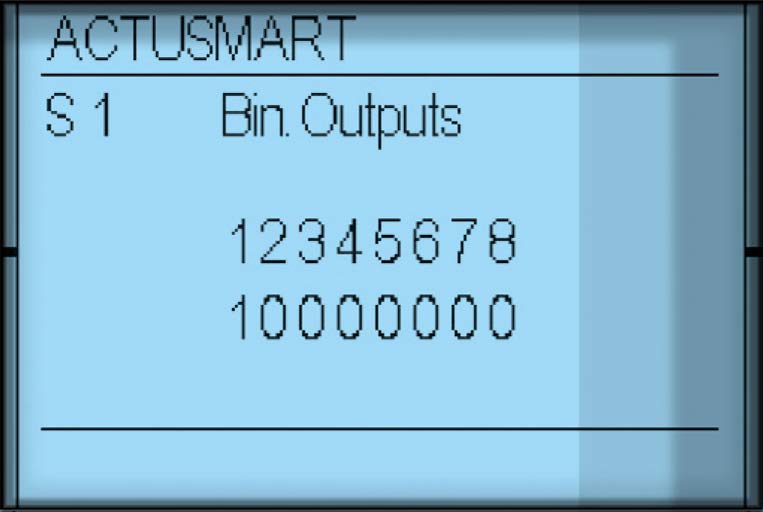

Binary Outputs

The display of the eight binary feedbacks (freely programm- able) provides information about communication with the control unit.

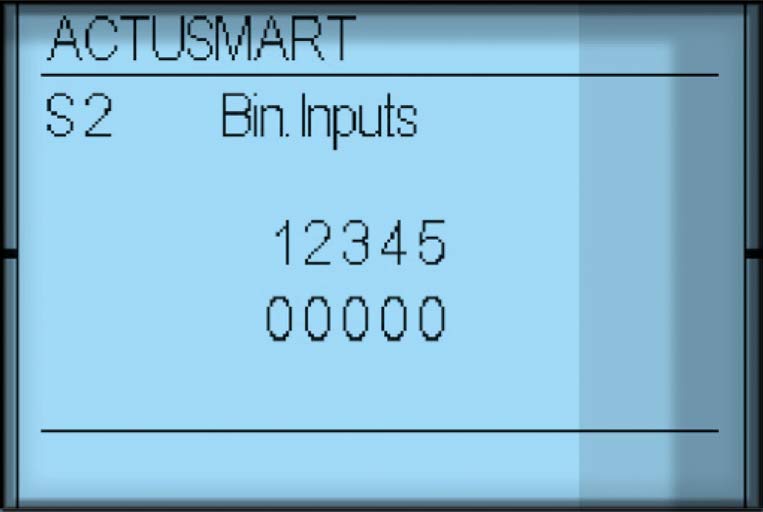

Binary Inputs

Display of five binary inputs (freely parameterizable), whereby the control unit represents incoming movement commands with 1 instead of 0.

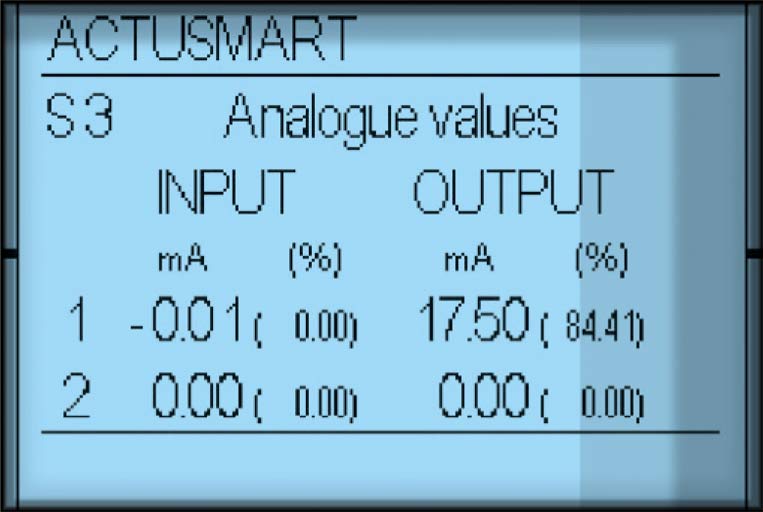

Analogue Values

Display of the analog 0/4–20-mA inputs and of the analog feed- backs from and to the control unit.

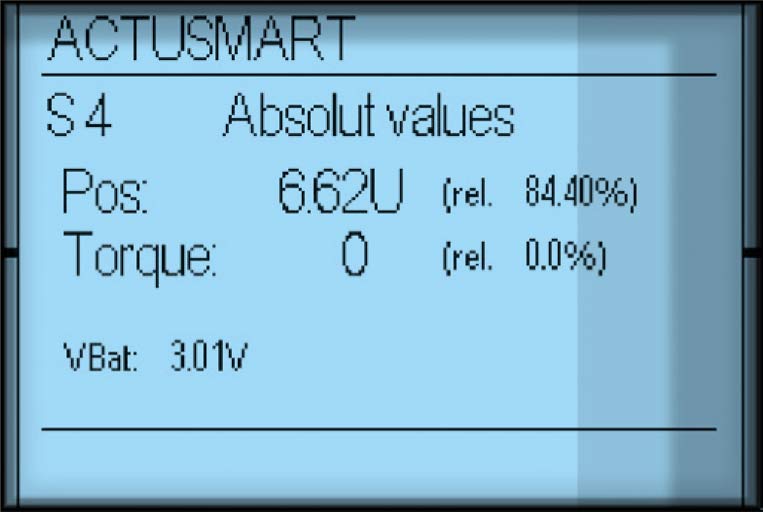

Absolut Values

Display of the absolute and relative values for positions and torques.

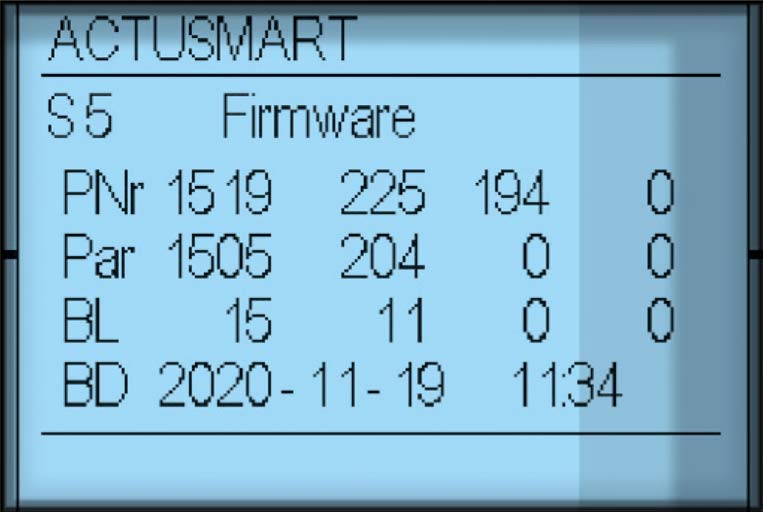

Firmware

Display of firmware (software version), including date.

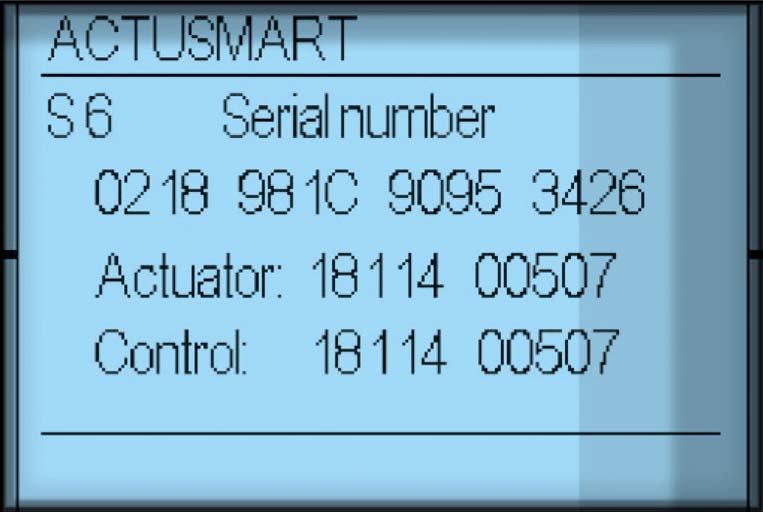

Serial Number

Display of the serial number of electronics, actuator and control unit.

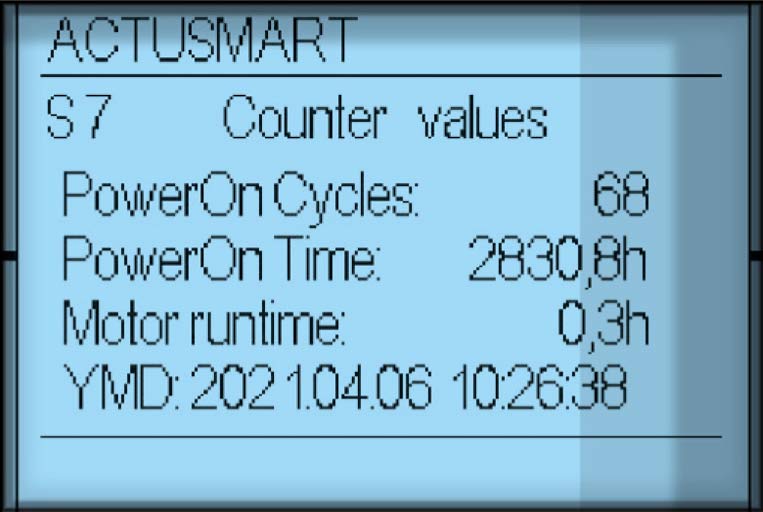

Counter Values

PowerOn cycles: How often has the actuator been turned on and off? Operating hours: Actuator under live voltage Motor run time: Motor in motion.